Adulteration is one of the biggest threats to the spice industry. It damages trust, leads to failed audits and causes recalls for importers. Many adulteration cases start not at the exporter level, but earlier in the supply chain.

To guarantee pure, export safe spices, Mira Masala LLP uses a multi stage anti adulteration protocol designed to eliminate risk at every point from sourcing to packaging.

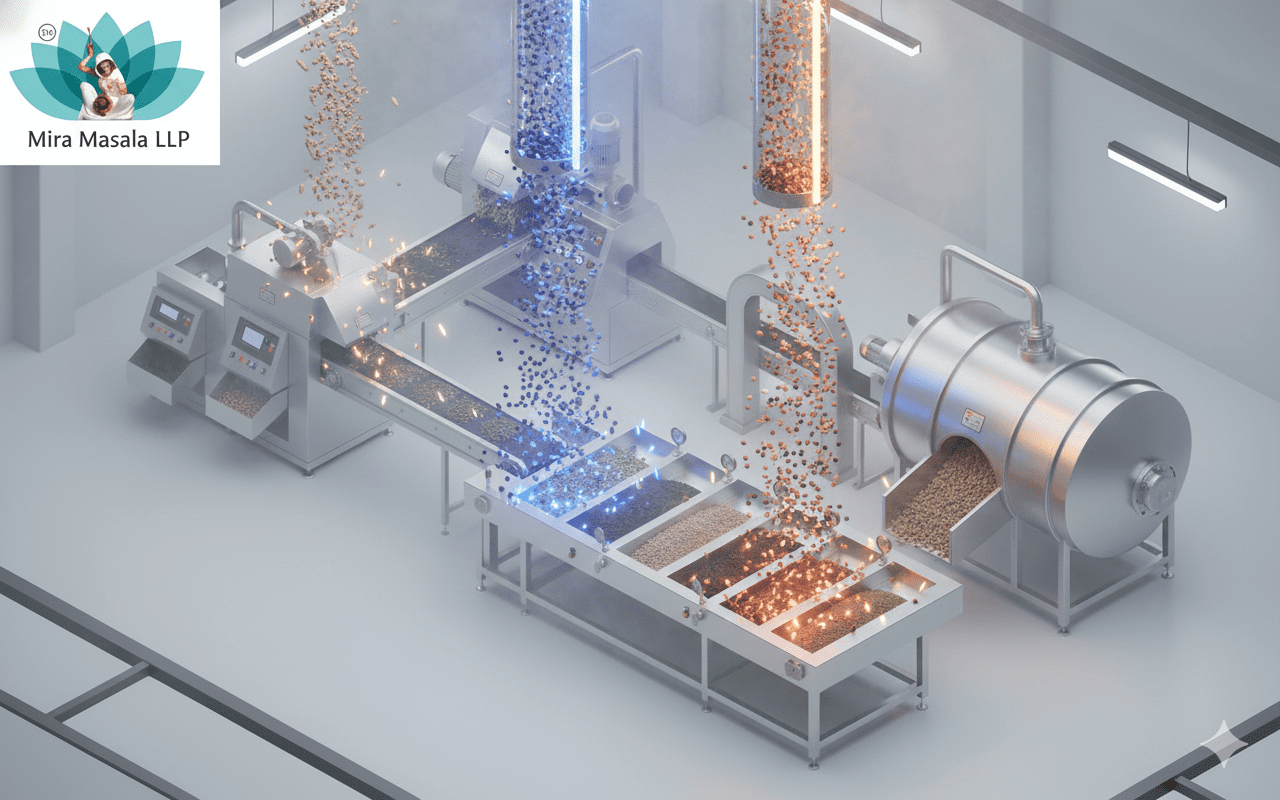

The 6 Stage Anti Adulteration Protocol

1. Verified Raw Material Sourcing

Mira Masala does not buy from unknown traders or mixed mandi lots. All raw material is sourced from trusted, verified partners who follow strict quality expectations.

2. Physical Cleaning And Separation

Spices pass through multiple cleaning stages including:

- Destoning

- Air classification

- Density and gravity separation

- Metal detection

This removes stones, dust, husk, metal fragments and other foreign materials.

3. Moisture Calibration

Excess moisture is a major cause of mold and weight manipulation. Mira Masala calibrates moisture to safe levels for each spice category to prevent quality loss in transit.

4. Microbial Control Through Safe Sterilization

We use globally accepted methods such as steam sterilization and controlled heat treatment. No chemicals or EtO are used at any stage.

5. Third Party Lab Testing

Every batch is tested for microbiology, aflatoxins where applicable, moisture and basic adulteration screening. Reports are provided to importers.

6. Tamper Proof Export Packaging

We use food grade liners, export safe bags and palletization to ensure the product remains clean, protected and stable throughout international transit.

Why This System Works

Adulteration prevention cannot be achieved by a single step. It requires a complete system that controls the product journey from source to shipment. Mira Masala’s structured process gives importers a reliable supply of clean, pure and compliant spices.